Beyond Components: How OEMs Can Thrive Through Servitization

- Dr. Arsham Mazaheri

- May 13, 2023

- 6 min read

Updated: Oct 12, 2023

We recently sat down with a prospective client, a respected Original Equipment Manufacturer (OEM), for a productive discussion. The conversation was lively and engaging, centered on their desire to renovate their revenue model and get more mature into servitization. But in the middle, they expressed a common concern: "Our product is a component of other manufacturers' products. We are only viewed as a component or spare-part provider rather than offering the finished machine from which the clients typically see their valued functions. How can a servitized business model be developed for such a product?

Indeed, this is a challenge many component manufacturers struggle with as they try to stay competitive in today's fast-paced, customer-centric environment. Servitization, or the transformation from selling products to delivering comprehensive solutions combining products and services, has huge potential for creating sustainable revenue streams and enhancing customer relationships. But how can component OEMs leverage servitization effectively when their products are not the final goods but integral parts of larger systems?

Let's dive into how OEMs like our client can shape a successful servitization strategy, even when the products they offer are components rather than standalone machines. Now remember, depends on what the component is, and how the larger system is dependent on your manufactured component, some of these services will need tuning before being able to be offered to your clients as a packaged value-adding service. In many cases, you may also be able to offer your services to the other OEMs, who use your product in their products, rather than to the end customer. Thus, becoming the Strategic Partner of other OEMs.

Strategic Partnerships

Strategic partnerships with other OEMs could open doors to jointly offer services that benefit end-users. Coordinated maintenance services, integrated performance optimization, or even joint PaaS offerings can be explored. These collaborations can strengthen your position in the value chain and enable you to offer comprehensive solutions that extend beyond the bounds of your component products.

Performance Optimization Services

As component OEMs, you have unique insights into your products and how they function within larger systems. You can always offer performance optimization services to help your customers or their customers, as the end consumer of the component, maximize the efficiency and productivity of their equipment. Regular check-ups, maintenance, tuning services, and even predictive analytics to prevent downtime before it occurs, can form part of your service portfolio. Moreover, this will not only generate a steady income stream but also solidify your reputation as partners in your customers' success, rather than mere suppliers.

Integration and Installation Services

Installing and integrating components into larger systems can sometimes be complex. As the manufacturer of these components, you are in the best position to offer integration and installation services. This is one of the ways you can offer your services to other OEMs than the end customer. By doing so, you ensure that your products function at their best from the start and reduce the likelihood of future issues, further improving customer satisfaction, which also helps the other OEMs to have satisfied customers. So, it is a win-win-win situation!

Training Services

Training is another area where you can add value. By offering training services, you help your customers, as other OEMs or the end customer, use and maintain your products more effectively, thereby maximizing the longevity and performance of the components. This can be done through on-site training, online courses, or even through augmented or virtual reality platforms, depending on the complexity of the components.

Component-as-a-Service (CaaS)

Taking a leaf from the Product-as-a-Service (PaaS) playbook, you can also explore the idea of Component-as-a-Service (CaaS). This would involve customers paying for the performance of the component, rather than buying it outright. This could be based on operating hours, throughput, or any other relevant metric. This approach, though requiring careful contract structuring and possibly the use of IoT technologies to monitor performance, can create a consistent revenue stream and bring you closer to the end customers' operations.

Extended Warranties and Insurance

Extended warranties and insurance programs for your components can provide customers with peace of mind and generate additional recurring revenue. These offerings can be particularly appealing for components that are critical to the operation of larger systems or that have high replacement costs.

Software Services

In the increasingly digital world, many components have software elements. You can offer software updates and support services, which can be a significant source of revenue and customer loyalty. This is particularly true as cybersecurity becomes increasingly important. Also, you can offer software solutions, which use the collected data from the components and the way they are used as well as other environmental and operational data, to help the end customer improve the performance or increase the output of their machines.

To give you some examples illustrating how you, as component OEMs, can offer value-added services, maybe we can consider the followings:

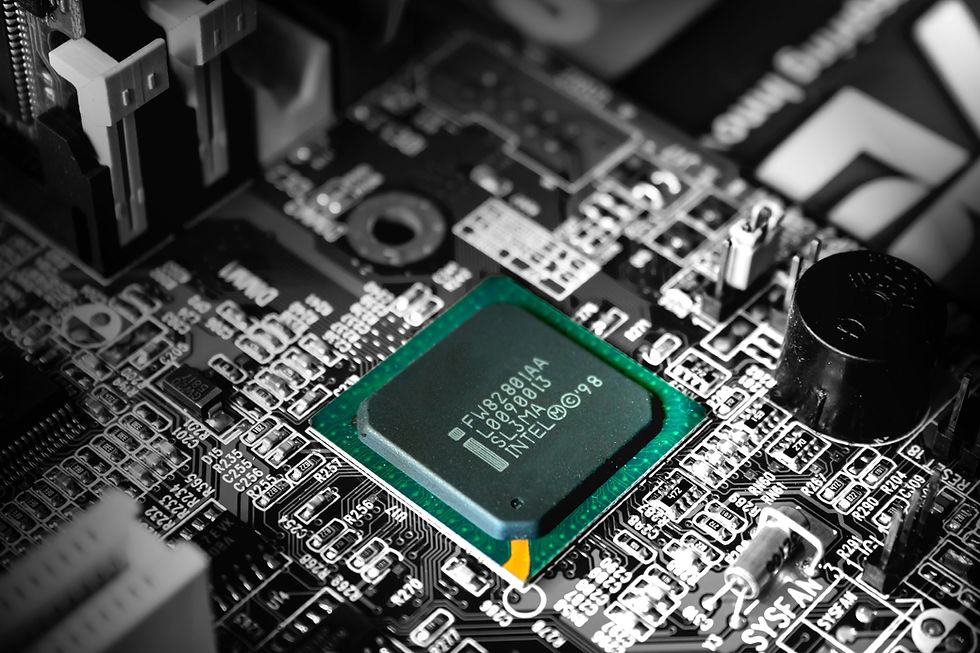

If you are a microchip manufacturer, your chips are integral components in various electronic devices. So, you may be able to provide “Technical Support Services” to help your customers troubleshoot issues and optimize the performance of your microchips within their devices; or be able to offer your technical expertise for “Custom Chip Design Services” to work closely with your customers in order to create microchips tailored to their specific needs.

If you are a battery manufacturer, your batteries might be used in everything from electric vehicles to renewable energy systems. So, since sustainability is becoming increasingly important, offering “Battery Recycling Services” could be a significant value addition for your customers; or you could also offer “Performance Monitoring Services” and use advanced analytics and IoT technologies to monitor the performance of your batteries in real-time and offer proactive maintenance services.

If you are a manufacturer of drives, which are essential components in many industrial systems, you could offer “Installation and Integration Services” to handle the installation and integration of your drives into your customers' systems, ensuring optimal performance from the outset; or with the help of IoT technologies, you could offer “Drive-as-a-Service”, where your customers pay for the performance of the drives rather than buying them outright.

If you are a manufacturer of hydraulic and pneumatic systems, your components might be integral parts of various machinery and equipment. So, you could offer “System Design Services”, helping your customers design efficient hydraulic and pneumatic systems that make the best use of your components; or given your technical expertise about your own products, you could offer “Maintenance Services”, helping your customers maximize the lifespan and performance of the components, and thus their main equipment or system.

If you are a sensor manufacturer, your sensors might be used in a wide range of applications, from industrial automation to healthcare. So, given the critical role of sensors in data collection, you could offer “Data Analysis Services” or develop various Software solutions and offer “Software-as-a-Services”, helping your customers derive valuable insights from the data collected by your sensors or make better decisions based on the dashboards and information your software drives from the collected data. Additionally, you could provide these services to many other OEMs for offering “Technical Support Services” to their customers for troubleshooting issues and customizing the functionality of their product to meet the specific needs of the end customer.

These examples illustrate the wide range of possibilities for servitization in the world of component OEMs. The key is to understand your customer's needs and how your unique capabilities can help meet those needs through value-added services.

All in all, the road to servitization for component OEMs, though challenging, is not an impossible one. Even though your products may be seen as integral parts of other larger systems, you can still provide a wide range of services that enhance your value proposition, deepen customer relationships, and provide sustainable revenue streams. Remember, the journey to servitization is not a one-size-fits-all process. It requires careful planning and execution. You must understand your customers' needs, the unique capabilities you bring to the table, and how you can best merge these two aspects to deliver value-added services. Furthermore, you must be ready to invest in new skills, technologies, and even cultural changes within your organization to successfully implement this shift.

So as component OEMs, you can redefine your roles in the value chain. By embracing servitization, you can transition from being viewed as mere suppliers or component providers to becoming integral partners in your customers' and their customers’ success. With a well-planned strategy and a customer-centric approach, you can indeed create a successful servitized business model, irrespective of whether your products are standalone systems or components of a larger whole.

Let's be in touch and please share with us about similar concepts or paths that you may have taken in your company. Remember that by embracing servitization, you can not only enhance your business sustainability but also contribute to a more collaborative, efficient, and customer-centric manufacturing landscape.

Comments